sandwich panel production line

Sandwich Panel automatic continuous production line

Multiple core materials used simultaneously!

Fully automated sandwich panel production line

Special features:

- Different core materials have a high degree of matching. One production line can meet the production of rock wool sandwich panels, polystyrene (EPS) sandwich panels, glass magnesium sandwich panels, and magnesium oxysulfide sandwich panels.

- High degree of automation, adapted to the Xinshuo LMS production line intelligent management system. The entire production line only requires 3-5 employees with very easy tasks!

- The production line can produce clean room panels or wall panels, and can also produce roof panels and other building panels by replacing the panel roll forming machine!

Production line composition

- Upper panel uncoiler

- Lower panel uncoiler

- Panel roll forming machine

- Core material feeder

- Sandwich panel composite machine

- cutting machine

- stacking machine

- winding and packing

- By adapting panel roll forming machines of different specifications and models, sandwich panels of different shapes and specifications can be produced.

Production line components

steel uncoiler

- This sandwich panel production line, used 4 fully automatic uncoilers. Two uncoilers are used for the upper panel, so that change the steel coils without stopping the production line. The steel coils from the two uncoilers pass through a automatically connects device. The same principle applies to the lower panel uncoiler. Each uncoiler is equipped with a hydraulic lifting device. The steel coils are placed on the lifting platform without adjustment, the steel coils will be automatically replace!

Core material feeder

- 4-axis multifunctional feeder, one loader can meet the needs of rock wool feeding and glass magnesium board core material feeding, free switching, polystyrene (EPS) feeding function can also be realized, which requires different silos!

panel composite machine

The panel composite machine is an important part, used to composite the glued panel and the core material. The technology of our composite machine is unique, the composite machine is short in size and has a fast production speed. It is equipped with a deviation correction function to prevent the board from deviating during the composite process!

The shape of the production roller can be customized to produce roof and wall panels of different specifications

cutting machine

Servo tracking cutting system, with two options, circular saw or band saw!

Circular saw is used in most cases, and double-head circular saw is used in Xinshuo’s self-developed circular saw cutting system. Double-head saw can not only meet the needs of mass production, but also improve cutting speed and cutting accuracy. Will reduce saw blade wear and burrs on the cutting surface!

stacking machine

- Use suction cup gripping method. If there is a need to produce roof panels, it is necessary to add sandwich panel flipping function.

- The type of the stacker is select depends on production needs.

- The stacker adopts servo motor with a PLC, make the stacking neatness and precision are very high.

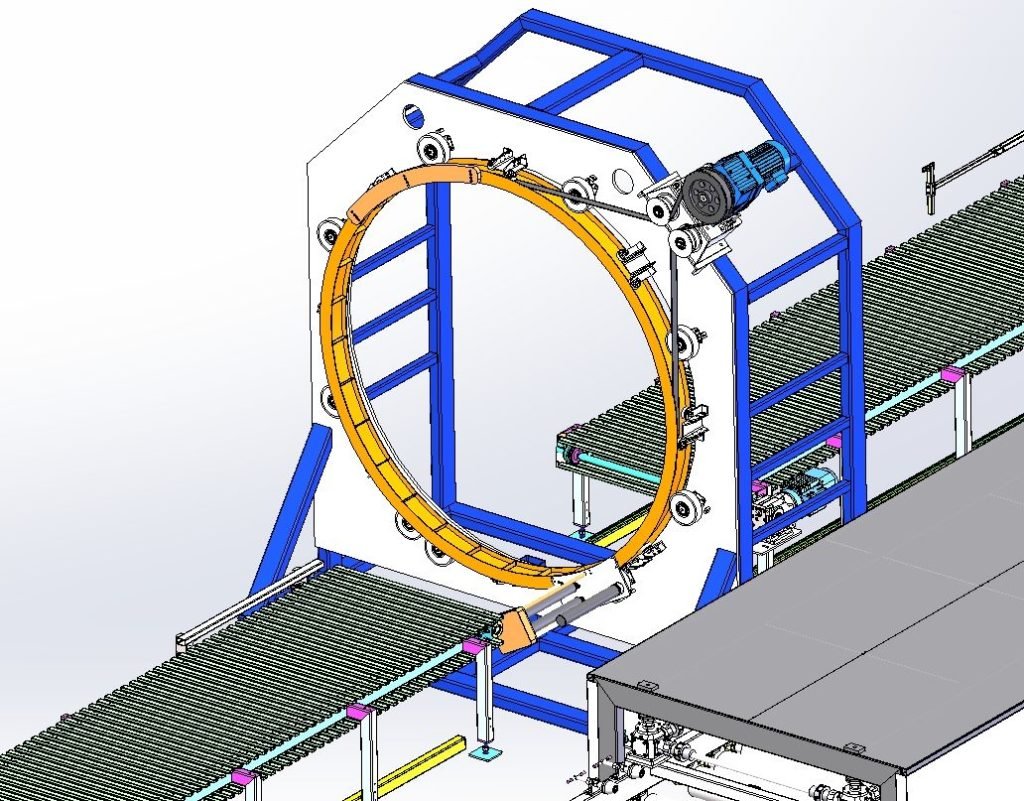

winding and packing

The wrapping machine is the last step of the production process, and it is now very common!

Production line advantages

Low degree of manual dependence: The whole production line is automatically adjusted, and the panel composite machine does not require much manual adjustment. The size is entered through the controller, and the production line is adjusted by itself.

Easy to operate: You just need to enter production parameters and adjust the equipment,the production process is not require manual intervention.

High degree of adaptability: The production line can be used to produce many types of plates.A universal production line that can be filled with different core materials.By adapting to different panel roll forming machines, different types of sandwich panels can be produced.

LMS system: The production line cooperates with the system to achieve one-click production, one-click management, and data statistics.

- At present, the sandwich panel industry (excluding polyurethane sandwich panels): Roof panels, Wall panels, Clean room panels, Double-sided steel strip edge-banding sandwich panels.The production line with the best versatility, the most advanced technology, and the whole process of automated production!

Get more information by following our social media !

LMS (production line management system )

- Xinshuo independently developed a fully automatic management system named Line Management System (LMS) Suitable for fully automated production lines.

- Fully automatic production line install with LMS will improve production efficiency and comprehensively reduce production and management costs. To achieve transform the factory to modernization and intelligence.

2.png)