The sandwich panel machine has revolutionized the production of modern construction materials, particularly in the manufacturing of PU (Polyurethane) and PIR (Polyisocyanurate) sandwich panels. These machines are engineered to create insulated panels that combine superior thermal performance, structural strength, and versatility, making them indispensable in industries ranging from construction to automotive manufacturing. The PU/PIR sandwich panel production line integrates state-of-the-art technology to streamline the production process, ensuring high-quality output that meets diverse industrial requirements. In this comprehensive guide, we will delve into the mechanics, components, benefits, and applications of the sandwich panel machine, emphasizing its role in producing PU/PIR panels.

What is a PU/PIR Sandwich Panel Machine?

A PU/PIR sandwich panel production line is an advanced sandwich panel machine designed to fabricate sandwich panels with a core of polyurethane or polyisocyanurate foam encased between two outer layers, typically steel or aluminum sheets. These panels are celebrated for their excellent insulation properties, lightweight design, and resistance to fire and moisture, making them a preferred choice for modern building solutions. The sandwich panel machine operates as a fully automated system, incorporating multiple stages—from raw material preparation to final cutting—into a seamless production flow.

The technology behind the sandwich panel machine allows manufacturers to produce panels of varying thicknesses, widths, and lengths, catering to specific project needs. Unlike manual or semi-automated methods, this machine ensures precision, consistency, and efficiency, reducing waste and labor costs while boosting output capacity. Whether used for roofing, wall cladding, or insulation boards, the PU/PIR sandwich panel machine delivers panels that meet stringent quality standards.

Key Components of the Sandwich Panel Machine

The PU/PIR sandwich panel production line is a complex assembly of components, each playing a critical role in ensuring the production of high-quality panels. Below is a detailed breakdown of its key elements:

Uncoiling System

The uncoiling system feeds metal coils—typically steel or aluminum—into the sandwich panel machine. It ensures a continuous supply of raw material, with hydraulic or motorized mechanisms to handle heavy coils efficiently.

Film Covering and Cutting System

This system applies protective films to the metal surfaces and trims them to precise dimensions before they enter the forming stage, enhancing durability and preparing the material for further processing.

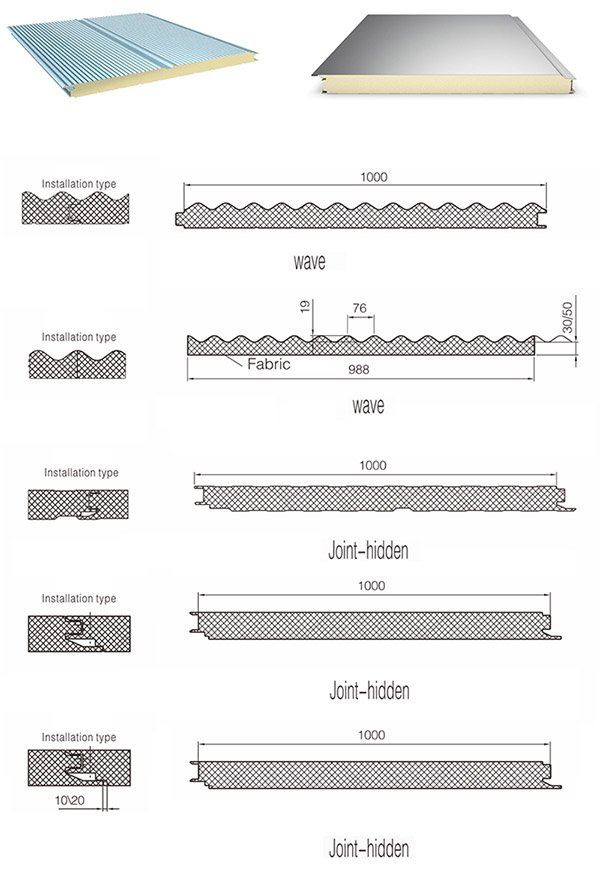

Roll Forming Machine

The roll forming machine shapes the outer metal layers into specific profiles, such as corrugated or flat designs, which improve the panels’ structural integrity and aesthetic appeal.

Preheating Oven

Before foaming, the preheating oven warms the metal sheets to an optimal temperature, ensuring proper adhesion and curing of the PU or PIR foam core.

High-Pressure Foaming System

The heart of the sandwich panel machine, this system injects PU or PIR foam between the metal layers under high pressure. It uses eco-friendly blowing agents like cyclopentane, ensuring minimal environmental impact and excellent insulation properties.

Double Belt Conveyor

The double belt conveyor presses the panels as the foam cures, maintaining uniform thickness and flatness. Its adjustable settings allow for customization of panel dimensions.

Cutting and Stacking System

Once cured, the panels are cut to specified lengths by an automated cutting system, followed by stacking for easy handling and transportation.

These components work in unison, making the sandwich panel machine a highly efficient and reliable tool for continuous production.

Technical Advantages of the Sandwich Panel Machine

The PU/PIR sandwich panel production line offers a range of technical advantages that distinguish it from other manufacturing equipment:

- Superior Insulation: PU and PIR foams provide exceptional thermal and acoustic insulation, reducing energy costs in buildings.

- High Efficiency: The sandwich panel machine’s continuous operation minimizes downtime, enabling manufacturers to meet large-scale production demands.

- Customizable Output: Adjustable parameters allow for panels with varying densities (40-60 kg/m³), thicknesses (20-200 mm), and surface finishes.

- Eco-Friendly Design: Uses non-CFC blowing agents, aligning with global sustainability standards and reducing greenhouse gas emissions.

- Durability and Strength: Panels exhibit high elastic strength and resistance to wear, making them suitable for harsh environments.

- Precision Engineering: Automated controls ensure consistent quality, with minimal human intervention and reduced error rates.

These features make the sandwich panel machine an indispensable asset for manufacturers aiming to produce high-performance, cost-effective panels.

Applications of PU/PIR Sandwich Panels

The versatility of the sandwich panel machine enables the production of PU/PIR panels for a wide array of applications across multiple industries:

- Construction Industry: Used in roofing, wall cladding, and insulation boards for residential, commercial, and industrial buildings, offering lightweight yet durable solutions.

- Cold Storage: Ideal for refrigerated warehouses and cold rooms due to their excellent thermal insulation properties.

- Metallurgy and Petroleum: Provides robust cladding and insulation for facilities exposed to extreme temperatures and corrosive conditions.

- Automotive Sector: Employed in manufacturing lightweight, insulated panels for vehicle bodies and trailers.

- Water Conservancy Projects: Supports infrastructure like dams and reservoirs with weather-resistant, high-strength panels.

- Prefabricated Structures: Perfect for modular buildings, offering fast assembly and energy-efficient performance.

The sandwich panel machine’s ability to produce panels tailored to these applications underscores its value in modern manufacturing.

Why Invest in a PU/PIR Sandwich Panel Machine?

Choosing a high-quality sandwich panel machine for PU/PIR panel production offers significant benefits for manufacturers:

- Cost Savings: Automation reduces labor costs, while energy-efficient designs lower operational expenses.

- Scalability: The sandwich panel machine can handle small batches or large-scale production, adapting to market demands.

- Enhanced Safety: Advanced dust-free foaming systems and ergonomic designs improve worker safety.

- Market Competitiveness: High-quality panels enhance product offerings, giving businesses an edge in the construction market.

The machine’s gantry lift-draw design eliminates the need for extensive foundations, while features like the 2+2 production mode and hot air circulation furnace optimize efficiency and quality. Constructed with welded steel plates and stress-relieved frames, the sandwich panel machine is built to withstand years of heavy use without deformation.

Conclusion

The PU/PIR sandwich panel production line represents the pinnacle of sandwich panel machine technology, offering a robust, efficient, and sustainable solution for producing high-quality insulated panels. From its precision-engineered components to its wide-ranging applications, this machine empowers manufacturers to meet the growing demand for advanced building materials. Whether you’re in construction, cold storage, or industrial manufacturing, investing in a sandwich panel machine ensures long-term productivity, quality, and profitability.