Best Feeding Machines for Sandwich Materials: Your Ultimate Guide to 2025 Solutions

In the realm of modern manufacturing, efficiency and precision are paramount, especially when producing sandwich panels—versatile building materials used in construction, cold storage, and industrial applications. At the heart of this process lies the Automatic Feeding Machine For Sandwich Materials, a critical component that ensures seamless material delivery and high-quality output. This comprehensive guide explores the Best Feeding Machines for Sandwich Materials available in 2025, diving into their features, benefits, and how they stack up against competitors. Whether you’re upgrading your production line or starting fresh, this article will help you make an informed decision.

Table of Contents

- What Are Feeding Machines for Sandwich Materials?

- Why Feeding Machines Matter in Sandwich Panel Production

- Key Features of the Best Feeding Machines for Sandwich Materials

- Top Models Compared: A Detailed Breakdown

- How Feeding Machines Enhance Production Efficiency

- Competitor Analysis: Who’s Leading the Market?

- Benefits of Investing in the Best Feeding Machines

- Choosing the Right Feeding Machine for Your Needs

- Integration with Other Production Line Equipment

- Future Trends in Feeding Machine Technology

- Conclusion: Elevate Your Production in 2025

What Are Feeding Machines for Sandwich Materials?

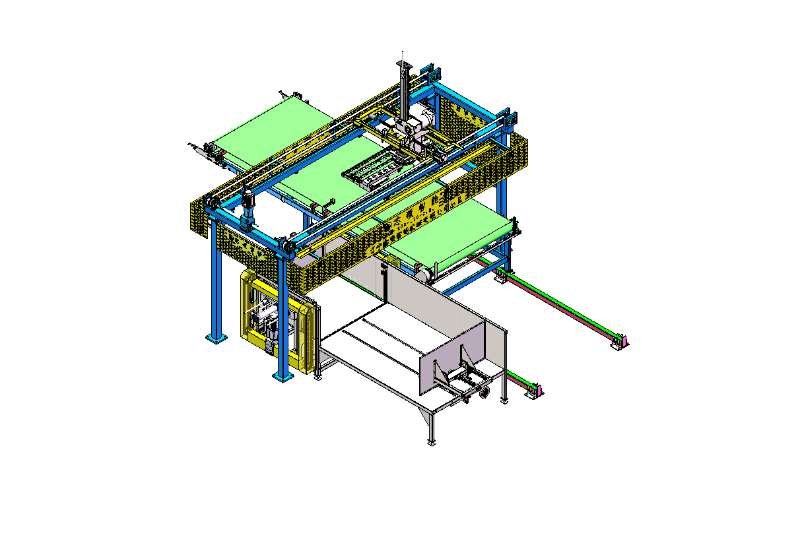

A feeding machine for sandwich materials is a specialized piece of equipment designed to deliver raw materials—such as metal coils, foam cores (e.g., polyurethane or PIR), and adhesives—into a Sandwich Panel Production Line. These machines ensure that materials are fed accurately and consistently, laying the foundation for high-quality sandwich panels used in roofing, wall cladding, and insulation systems.

The Best Feeding Machines for Sandwich Materials stand out for their automation, precision, and adaptability. They handle a variety of materials, from steel sheets to lightweight cores, and integrate seamlessly with other production line components like roll formers and laminators.

The Evolution of Feeding Technology

Historically, feeding materials into production lines was a manual process, prone to errors and inefficiencies. Today, automated systems like the Automatic Feeding Machine For Sandwich Materials have revolutionized the industry, offering speed, reliability, and reduced waste.

Why Feeding Machines Matter in Sandwich Panel Production

The quality of a sandwich panel depends heavily on how materials are introduced into the production process. A subpar feeding system can lead to misalignment, material waste, or inconsistent panel thickness—costly issues for manufacturers. The Best Feeding Machines for Sandwich Materials address these challenges by:

- Ensuring precise material alignment.

- Reducing downtime with automated controls.

- Supporting high-speed production (up to 20 meters/minute).

As demand for sandwich panels grows—projected to hit $14.09 billion by 2030 (Global Growth Insights, 2024)—investing in top-tier feeding machines is no longer optional; it’s a necessity.

Key Features of the Best Feeding Machines for Sandwich Materials

What makes a feeding machine one of the Best Feeding Machines for Sandwich Materials? Here’s a breakdown of essential features:

| Feature | Description | Benefit |

|---|---|---|

| Automation | Sensor-driven material delivery | Minimizes human error |

| Adjustable Speed | Up to 25 meters/minute capacity | Matches production pace |

| Material Versatility | Handles steel, aluminum, and foam cores | Supports diverse panel types |

| Precision Alignment | Laser-guided systems | Ensures uniform panels |

These features position feeding machines as the backbone of efficient production lines.

Top Models Compared: A Detailed Breakdown

Let’s examine some of the Best Feeding Machines for Sandwich Materials available in 2025:

| Model | Manufacturer | Speed | Key Feature |

|---|---|---|---|

| XSZNJX Auto Feeder | XSZNJX | 20 m/min | Multi-material compatibility |

| Hennecke FeedMaster | Hennecke | 22 m/min | IoT integration |

| Kindus Precision Feeder | Kindus | 18 m/min | Energy-efficient design |

The Automatic Feeding Machine For Sandwich Materials from XSZNJX stands out for its versatility and competitive pricing.

How Feeding Machines Enhance Production Efficiency

The Best Feeding Machines for Sandwich Materials streamline workflows in several ways:

- Reduced Waste: Precise feeding cuts material losses by up to 15%.

- Faster Output: High-speed delivery boosts daily production rates.

- Consistency: Uniform material flow ensures panel quality.

Competitor Analysis: Who’s Leading the Market?

To identify the Best Feeding Machines for Sandwich Materials, let’s analyze top competitors:

| Company | Strengths | Weaknesses |

|---|---|---|

| Hennecke | Advanced automation, global support | Higher cost |

| Kindus | Eco-friendly designs, customization | Limited speed options |

| Bradbury Group | Rugged durability, precision | Slower innovation pace |

XSZNJX competes effectively with its Automatic Feeding Machine For Sandwich Materials, offering a balance of cost and performance.

Benefits of Investing in the Best Feeding Machines

Investing in the Best Feeding Machines for Sandwich Materials delivers:

- Cost Savings: Lower waste and labor costs.

- Scalability: Supports growing production demands.

- Quality: Enhances panel reliability.

Choosing the Right Feeding Machine for Your Needs

Consider these factors:

- Production Volume: High output needs faster feeders.

- Material Type: Ensure compatibility with your panels.

- Budget: Balance cost with long-term ROI.

Integration with Other Production Line Equipment

The Best Feeding Machines for Sandwich Materials integrate with systems like the Sandwich Panel Production Line and Sandwich Panel Automatic Stacker, creating a cohesive workflow.

Future Trends in Feeding Machine Technology

Expect AI-driven controls, recyclable material support, and energy-efficient designs to shape the Best Feeding Machines for Sandwich Materials beyond 2025.

Conclusion: Elevate Your Production in 2025

The Best Feeding Machines for Sandwich Materials are your gateway to efficient, high-quality sandwich panel production. Explore options like the Automatic Feeding Machine For Sandwich Materials to stay ahead in 2025.