Revolutionizing Construction Efficiency: The Future of Sandwich Panel Manufacturing

In today’s fast-paced construction and industrial manufacturing sectors, the demand for high-quality, lightweight, and durable sandwich panels continues to surge. These panels, composed of insulating core materials sandwiched between two metal or composite sheets, are widely used in roofing, wall cladding, and cleanroom applications. To meet this demand, Xinshuo Industrial Solutions has pioneered the sandwich panel production line, a fully automated, versatile system designed to optimize productivity, reduce labor costs, and ensure precision across diverse applications.

1. Introduction to Xinshuo’s Sandwich Panel Automatic Continuous Production Line

Xinshuo’s Sandwich Panel Automatic Continuous Production Line represents a breakthrough in industrial automation. Tailored for manufacturers seeking efficiency and adaptability, this system integrates cutting-edge technology to produce panels with rock wool, EPS (expanded polystyrene), glass-magnesium, and magnesium oxysulfide cores—all on a single production line.

Key Advantages:

- Multi-Core Material Compatibility: Switch seamlessly between core materials without downtime.

- Full Automation: Operated by just 3–5 personnel, minimizing human error and labor costs.

- Smart LMS Integration: Real-time monitoring and data-driven optimization via Xinshuo’s proprietary Line Management System (LMS).

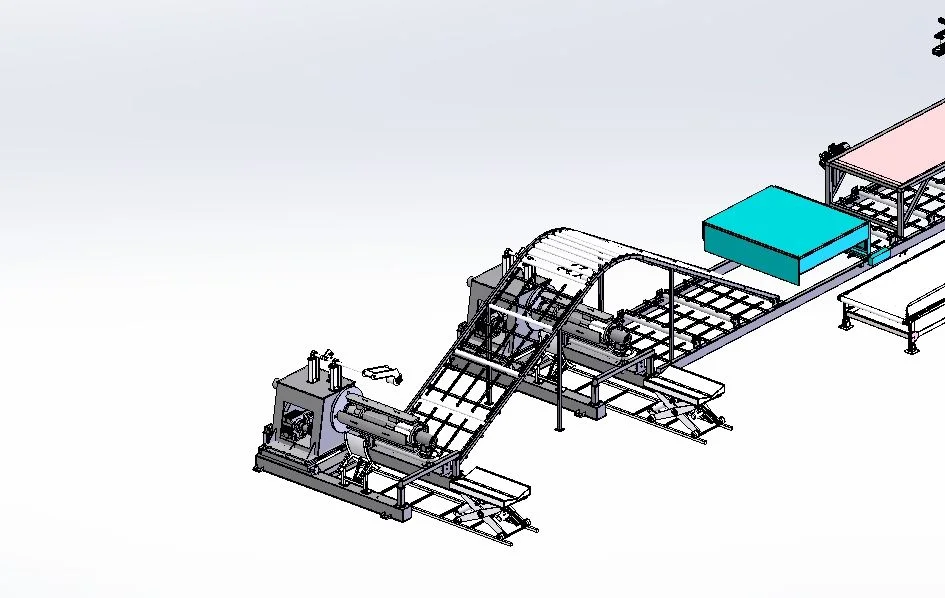

2. Core Components of the Production Line

The production line comprises eight modular units, each engineered for precision and reliability:

| Component | Function | Technical Highlights |

|---|---|---|

| Steel Uncoilers | Feed upper and lower metal sheets continuously. | Dual uncoilers with hydraulic lifting and automatic splicing for uninterrupted operation. |

| Panel Roll Forming Machine | Shapes metal sheets into profiles for walls, roofs, or cleanroom panels. | Customizable rollers for diverse panel dimensions (e.g., trapezoidal, sinusoidal). |

| Core Material Feeder | Supplies insulation cores (rock wool, EPS, etc.) to the composite machine. | 4-axis multifunctional feeder with silos for rapid material switching. |

| Sandwich Panel Composite Machine | Bonds metal sheets and core material under controlled pressure. | Short-length design with laser-guided alignment to prevent deviations. |

| Servo Tracking Cutting System | Cuts panels to precise lengths using circular or band saws. | Double-head circular saw reduces blade wear and ensures smooth edges. |

| Stacking Machine | Organizes finished panels with suction cups or flipping mechanisms. | PLC-controlled servo motors ensure uniform stacking for palletizing. |

| Wrapping & Packing Unit | Secures panels for storage and transportation. | Fully automated film-wrapping with tension control. |

3. Technological Innovations Driving Efficiency

A. Automation & Labor Optimization

Unlike traditional lines requiring 10+ workers, Xinshuo’s system operates with 3–5 technicians overseeing automated processes. The LMS platform enables:

- One-click parameter adjustments (e.g., panel length, core thickness).

- Predictive maintenance alerts to minimize downtime.

- Real-time production analytics for cost and energy optimization.

B. Adaptive Design for Diverse Applications

By swapping the roll forming machine’s rollers, the line produces:

- Roofing panels with enhanced weather resistance.

- Wall panels with fire-retardant cores.

- Cleanroom panels meeting ISO 14644 standards.

C. Precision Cutting & Quality Assurance

The servo tracking system ensures cuts with tolerances of ±0.5 mm, while the composite machine’s infrared sensors eliminate misalignment.

4. Why Choose Xinshuo’s Production Line?

A. Unmatched Versatility

- Material Flexibility: Produce panels with rock wool (fireproof), EPS (lightweight), or glass-magnesium (high-strength) cores.

- Output Customization: Adjust line speed (up to 15 m/min) for high-volume or specialized orders.

B. Cost-Effective ROI

- Energy Savings: LMS optimizes power consumption by 20%.

- Reduced Waste: Precision feeding and cutting minimize material loss.

C. Global Success Stories

Deployed in Uzbekistan, Vietnam, and Russia, Xinshuo’s lines have enabled clients to:

- Cut production costs by 35%.

- Increase output capacity by 200%.

5. Conclusion: Elevate Your Manufacturing Capabilities

For enterprises aiming to dominate the sandwich panel market, Xinshuo’s sandwich panel production line offers a future-proof solution. Combining automation, adaptability, and intelligent management, this system empowers manufacturers to meet evolving industry demands while maintaining competitive pricing.

Contact Xinshuo Industrial Solutions today to schedule a demo or request a customized retrofitting plan tailored to your facility’s needs.