In the construction and manufacturing industries, the demand for high-quality, efficient, and versatile sandwich panel production solutions has been on the rise. Xinshuo’s Sandwich Panel Automatic Continuous Production Line is a cutting-edge offering that meets these demands with its advanced features, comprehensive composition, and numerous advantages. This article will delve deep into every aspect of this remarkable production line, providing you with in-depth insights and detailed information.

I. Introduction to Sandwich Panel Production Line

Sandwich panels have become increasingly popular in various applications due to their excellent insulation properties, high strength-to-weight ratio, and aesthetic appeal. A sandwich panel typically consists of two outer layers (skins) and a core material in between. The outer layers are usually made of materials like steel, aluminum, or fiberglass, while the core can be rock wool, polystyrene (EPS), glass magnesium, or magnesium oxysulfide.

Xinshuo’s Sandwich Panel Automatic Continuous Production Line is designed to streamline the production process of these panels, ensuring high productivity, consistent quality, and flexibility in production. You can learn more about this innovative production line by visiting sandwich panel production line

II. Special Features of the Production Line

A. High Degree of Core Material Matching

One of the most outstanding features of this production line is its ability to work with multiple core materials simultaneously. Different core materials have a high degree of matching within the system. This means that a single production line can meet the production requirements of various types of sandwich panels, including rock wool sandwich panels, polystyrene (EPS) sandwich panels, glass magnesium sandwich panels, and magnesium oxysulfide sandwich panels. This versatility significantly increases the value of the production line for manufacturers, as they can adapt to different customer demands without the need for multiple dedicated production lines.

B. High Automation Level

The production line boasts a high degree of automation, which is a game-changer in the manufacturing process. It is adapted to the Xinshuo LMS production line intelligent management system. With this advanced system in place, the entire production line only requires 3 – 5 employees, and their tasks are relatively easy. This not only reduces labor costs but also minimizes the potential for human error, ensuring a more consistent and reliable production process.

C. Versatile Panel Production

The production line is incredibly versatile when it comes to the types of panels it can produce. It can produce clean room panels or wall panels with ease. Moreover, by simply replacing the panel roll forming machine, it can also produce roof panels and other building panels. This adaptability makes it suitable for a wide range of construction projects, from small-scale residential buildings to large commercial and industrial complexes.

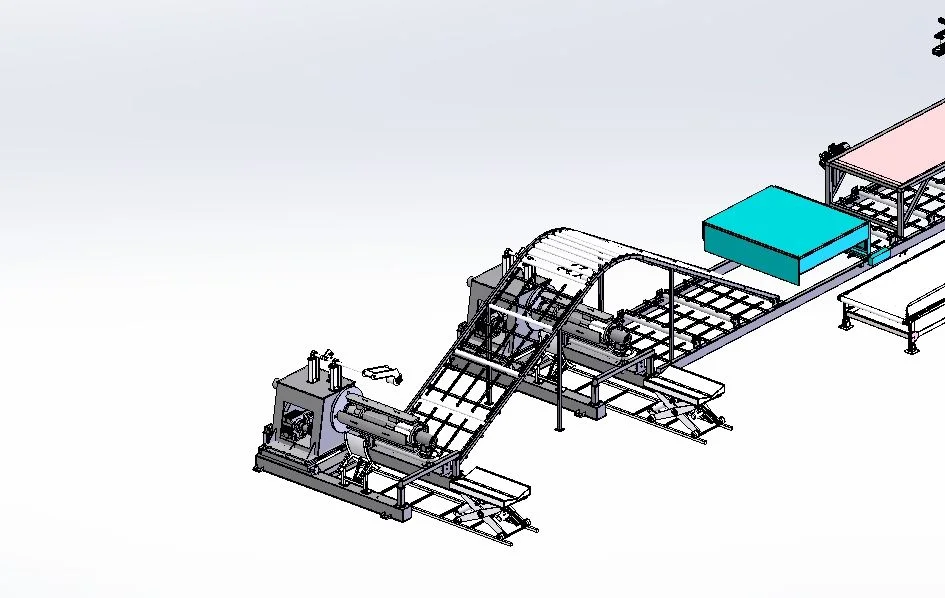

III. Composition of the Production Line

A. Upper Panel Uncoiler

The production line starts with the upper panel uncoiler. This component plays a crucial role in feeding the upper panel material into the production process. In this sandwich panel production line, 4 fully automatic uncoilers are used, with two specifically dedicated to the upper panel. This setup allows for seamless changeovers of steel coils without stopping the production line. The steel coils from the two uncoilers pass through an automatically connecting device, ensuring a smooth flow of material. Each uncoiler is equipped with a hydraulic lifting device. This means that steel coils can be placed on the lifting platform without the need for manual adjustment, and they will be automatically replaced when required.

B. Lower Panel Uncoiler

Similar to the upper panel uncoiler, the lower panel uncoiler is responsible for feeding the lower panel material. It follows the same principle as the upper panel uncoiler, with two uncoilers for the lower panel and an automatic connection device. The hydraulic lifting feature also ensures easy and efficient coil replacement, contributing to the overall smooth operation of the production line.

C. Panel Roll Forming Machine

The panel roll forming machine is a key component in shaping the panels. By adapting panel roll forming machines of different specifications and models, sandwich panels of different shapes and specifications can be produced. This flexibility allows manufacturers to meet the diverse requirements of their customers, whether it’s for standard-sized panels or custom-designed ones for unique construction projects.

D. Core Material Feeder

The core material feeder is a 4-axis multifunctional feeder. This single loader can meet the needs of rock wool feeding and glass magnesium board core material feeding, allowing for free switching between these two materials. Additionally, the polystyrene (EPS) feeding function can also be realized, although this requires different silos. This multifunctional design simplifies the production process and reduces the need for multiple separate feeding systems.

| Core Material | Feeding System Compatibility |

|---|---|

| Rock Wool | Yes |

| Glass Magnesium Board | Yes |

| Polystyrene (EPS) | Requires separate silos |

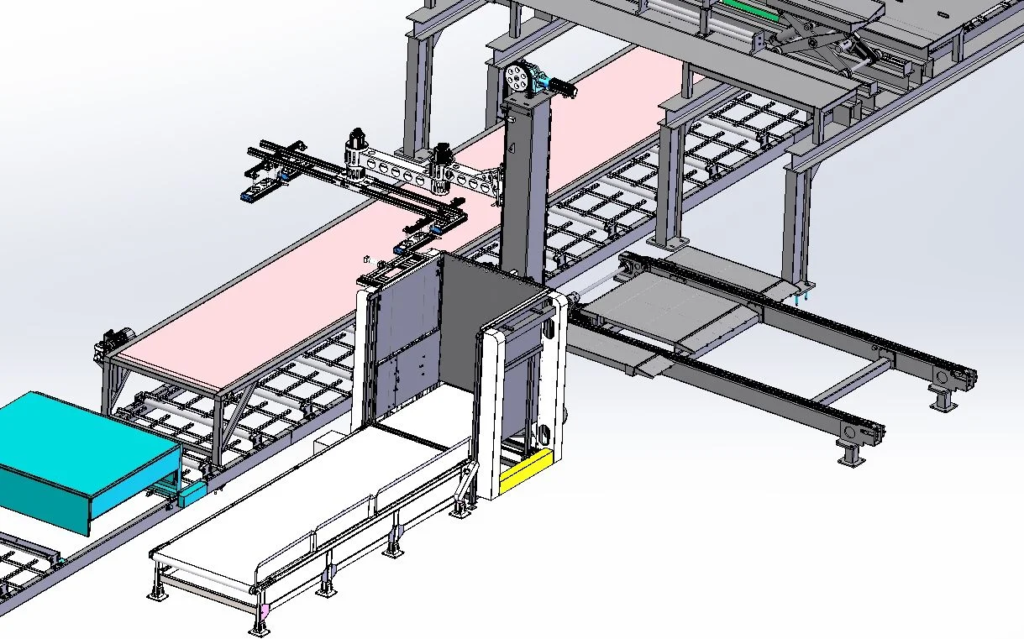

E. Sandwich Panel Composite Machine

The panel composite machine is an essential part of the production line. Its main function is to composite the glued panel and the core material. Xinshuo’s composite machine stands out with its unique technology. It is compact in size, which saves valuable floor space in the production facility, and yet it has a fast production speed. Moreover, it is equipped with a deviation correction function. This feature is crucial as it prevents the board from deviating during the composite process, ensuring that the final sandwich panels are of high quality and dimensionally accurate. The shape of the production roller can also be customized, enabling the production of roof and wall panels of different specifications.

F. Cutting Machine

The cutting machine is equipped with a servo tracking cutting system, offering two options: circular saw or band saw. In most cases, the circular saw is used. Xinshuo’s self-developed circular saw cutting system features a double-head circular saw. This double-head design has several advantages. It not only meets the needs of mass production but also significantly improves the cutting speed and accuracy. Additionally, it reduces saw blade wear and minimizes burrs on the cutting surface, resulting in a cleaner and more precise cut.

G. Stacking Machine

The stacking machine uses the suction cup gripping method to handle the finished sandwich panels. If there is a need to produce roof panels, an additional sandwich panel flipping function can be added. The type of stacker is selected based on production needs. The stacker is equipped with a servo motor and a PLC (Programmable Logic Controller), which ensures that the stacking neatness and precision are very high. This is important for efficient storage and transportation of the panels.

H. Winding and Packing

The winding and packing stage is the final step in the production process. The wrapping machine, which is commonly used in this stage, ensures that the finished sandwich panels are properly packaged for storage or transportation. This protects the panels from damage during handling and transit.

IV. Production Line Components in Detail

A. Steel Uncoiler

As mentioned earlier, the use of 4 fully automatic uncoilers in the production line is a significant advantage. The hydraulic lifting device on each uncoiler simplifies the process of loading and replacing steel coils. This not only saves time but also reduces the physical labor required. The automatic connection device between the two upper panel uncoilers and the two lower panel uncoilers ensures a continuous supply of material, minimizing production downtime.

B. Core Material Feeder – Four-axis Multi-function Automatic Feeding Machine – 2

The four-axis multi-function automatic feeding machine is designed to handle different core materials with ease. Its ability to switch between rock wool and glass magnesium board feeding without significant reconfiguration is a major benefit. The option to add EPS feeding with the use of different silos further expands the production line’s capabilities. This feeder’s design ensures accurate and consistent feeding of the core material, which is essential for the quality of the final sandwich panels.

V. Production Line Advantages

A. Low Degree of Manual Dependence

One of the most significant advantages of this production line is its low degree of manual dependence. The entire production line is automatically adjusted, and the panel composite machine, in particular, requires very little manual intervention. Operators only need to enter the size and other relevant parameters through the controller, and the production line will adjust itself accordingly. This reduces the need for extensive manual labor and also decreases the chances of human error, resulting in higher production quality.

B. Easy to Operate

The production line is designed to be user-friendly. All that operators need to do is enter the production parameters and make some basic adjustments to the equipment. Once the production process starts, it does not require continuous manual intervention. This simplicity of operation makes it accessible to a wider range of workers, even those with limited technical skills.

C. High Degree of Adaptability

The production line’s high degree of adaptability is a major selling point. It can be used to produce many types of plates, making it a universal solution for sandwich panel manufacturers. By filling different core materials and adapting to different panel roll forming machines, it can produce a wide variety of sandwich panels to meet the diverse needs of the market.

D. LMS System Integration

The integration of the production line with the Xinshuo LMS (Line Management System) is a game-changer. This fully automatic management system, developed by Xinshuo, is suitable for fully automated production lines. When installed on the sandwich panel production line, it offers several benefits. It enables one-click production and one-click management, streamlining the production process. Additionally, it can perform data statistics, which helps manufacturers analyze production efficiency, identify areas for improvement, and make informed decisions. This integration also contributes to the transformation of the factory towards modernization and intelligence.

VI. Applications in the Sandwich Panel Industry

At present, in the sandwich panel industry (excluding polyurethane sandwich panels), this production line is widely used for various types of panels. It can produce roof panels, wall panels, clean room panels, and double-sided steel strip edge-banding sandwich panels. Its versatility, advanced technology, and fully automated production process make it the top choice for manufacturers looking to optimize their production operations and meet the diverse demands of the market.

VII. Contact Information and Social Media Presence

If you are interested in learning more about the Sandwich Panel Automatic Continuous Production Line or getting a retrofitting plan for your existing production setup, you can contact Xinshuo. You can also follow their social media channels – Facebook, Linkedin, Vk, and Youtube – to get more information, stay updated on the latest product developments, and connect with the company.

In conclusion, Xinshuo’s Sandwich Panel Automatic Continuous Production Line is a remarkable piece of equipment that combines advanced technology, versatility, and efficiency. With its unique features, comprehensive composition, and numerous advantages, it is well-positioned to meet the challenges and opportunities in the modern sandwich panel manufacturing industry. Whether you are a small-scale producer looking to upgrade your production capabilities or a large enterprise seeking to optimize your operations, this production line is definitely worth considering.