Xinshuo Intelligent delivers fully automated sandwich panel production lines engineered for continuous operation, consistent quality, and fast ramp-up on site.

From raw material feeding and roll forming to lamination, curing, cutting, and stacking, each section is integrated under PLC control and designed to scale with your factory’s throughput targets.

Why Choose Xinshuo Sandwich Panel Lines?

- Flexible Panel Types: PU, PIR, EPS, and mineral/rock wool.

- High Production Speed: 3–10 m/min (adjustable).

- Custom Panel Sizes: Width 600–1250 mm, thickness 40–250 mm.

- Integrated Automation: Roll forming, lamination, curing, cutting, stacking under PLC/HMI.

- Servo-Tracking Compounding: Tight synchronization during continuous lamination for accuracy.

- Double-Belt Curing: Uniform pressure & heat for flatness and strong bonding.

- LMS (Line Management System): Real-time line monitoring, recipe management, and OEE-style insights.

- Turnkey Service: Design, manufacturing, on-site installation, training & lifetime support.

Learn more about our latest innovations in adhesive application and automation:

Innovations in Sandwich Panel Production.

Technical Specifications

| Item | Specification Range |

|---|---|

| Panel Types | PU, PIR, EPS, Mineral/Rock Wool |

| Panel Width | 600–1250 mm |

| Panel Thickness | 40–250 mm |

| Production Speed | 3–10 m/min (adjustable) |

| Forming Stations | 18–24 sets |

| Heating System | Electric / Thermal oil |

| Foaming System | High-pressure PU/PIR foaming machine |

| Cutting System | Flying saw or double saw |

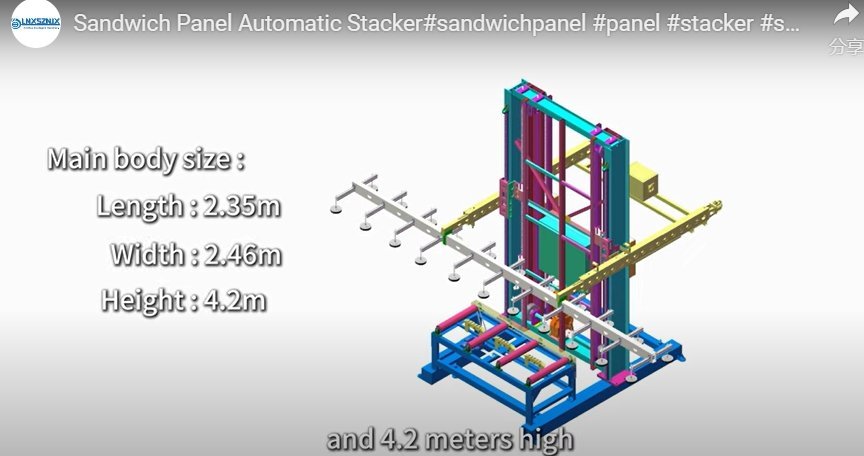

| Stacking System | Fully automatic |

| Control System | PLC with touchscreen HMI & LMS |

| Total Power | 100–180 kW (configuration-dependent) |

For intelligent roll forming details, see

Highly Intelligent Roll Forming Machines.

Production Process

- Coil feeding & uncoiling

- Upper & lower sheet roll forming

- Core forming & lamination (PU/PIR foaming or EPS/mineral wool laying)

- Double-belt curing (heating & flattening)

- Precision cutting (flying saw)

- Automatic stacking & packing

New to the process? Read

Key Steps in the Sandwich Panel Production Line Process.

Layout & Customization

We provide custom factory layout design to optimize workflow and space. Choose between:

- Single continuous line for one core material

- Multi-purpose line for both PU/PIR and mineral wool

- Dedicated profiles for roof, wall, cold storage, and clean room panels

Explore the main units and their roles in

Key Components of a Sandwich Panel Production Line.

Applications

- Industrial and commercial building roofs & walls

- Cold storage and refrigeration facilities

- Clean rooms & laboratories

- Prefabricated houses and modular buildings

For materials and process insights, see

From Raw Materials to Finished Product.

After-Sales Service

- On-site installation & commissioning

- Operator training

- 12–24 months warranty

- Lifetime technical support & spare parts supply

- LMS-enabled digital records for maintenance & traceability

FAQ

- Can one line support multiple core materials?

- Yes. With the correct subsystems and recipes, a line can handle PU/PIR foaming and also EPS/mineral wool feeding.

- How do you ensure adhesion quality at continuous speed?

- Servo-tracking compounding plus double-belt curing keeps pressure and heat consistent, and automated adhesive application ensures uniform coverage.

- Can you retrofit an older line with automation and digital management?

- Yes. We provide integrated upgrades and the LMS system to digitalize production and management.

- Where can I learn about each unit in detail?

- See Key Components and

Intelligent Roll Forming Machines.

Related Reading

Ready to Plan Your Line?

Tell us your target panel sizes, profiles, and core materials. We’ll return a layout proposal and configuration list with clear upgrade paths for future capacity gains.