Xinshuo Intelligent Production Line: Revolutionizing Manufacturing with Sandwich Panels, Clean Room Panels, and C&Z Steel Purlins

In today’s fast-paced industrial world, manufacturers face increasing pressure to deliver high-quality products efficiently while minimizing costs and maintaining competitiveness. Xinshuo Intelligent Production Line emerges as a transformative force in this landscape, offering state-of-the-art automation solutions for producing sandwich panels, clean room panels, and C&Z steel purlins. With over a decade of experience in mechanical automation, Xinshuo provides fully automated production lines, retrofitting services, and intelligent management systems designed to modernize factories and optimize operations.

reduces labor dependency, and elevates corporate image. From sandwich panel manufacturing to clean room solutions and structural steel purlin production, Xinshuo’s intelligent systems cater to diverse industries, including construction, pharmaceuticals, electronics, and more. Whether you’re seeking to upgrade existing equipment or establish a new production facility, Xinshuo offers customized, high-performance solutions to meet your needs.

1. Introduction to Xinshuo Intelligent Production Line

Xinshuo Intelligent Production Line is a pioneering name in mechanical automation, specializing in advanced manufacturing systems for sandwich panels, clean room panels, and C&Z steel purlins. With a mission to drive industrial modernization, Xinshuo combines cutting-edge technology—such as robotics, artificial intelligence, and precision engineering—with a customer-centric approach to deliver solutions that transform traditional factories into intelligent, efficient hubs.

For over ten years, Xinshuo has been at the forefront of automation, helping manufacturers worldwide achieve higher productivity, superior product quality, and significant cost savings. Their portfolio includes fully automated production lines, retrofitting services for aging equipment, laser cutting capabilities, and the proprietary Line Management System (LMS), which integrates seamlessly with their machinery to enable digital factory management.

2. Sandwich Panel Production Line: Building the Future with Automation

2.1 Understanding Sandwich Panels

Sandwich panels are versatile composite materials widely used in construction and industrial applications. They consist of two outer layers—typically steel or aluminum—and an insulating core that provides thermal, acoustic, and structural properties. The core material varies depending on the panel’s intended use, with common options including rock wool, polystyrene (EPS), polyurethane (PU), glass magnesium, and magnesium oxide sulfide.

These panels are prized for their lightweight design, durability, and ease of installation, making them a popular choice for walls, roofs, and partitions in buildings ranging from warehouses to residential homes. Their insulation properties also contribute to energy efficiency, reducing heating and cooling costs—a critical factor in sustainable construction.

The global sandwich panel market is projected to grow steadily, driven by demand in construction, cold storage, and industrial sectors. According to industry reports, the market size was valued at approximately $12 billion in 2022 and is expected to expand at a CAGR of 5-6% through 2030, reflecting the increasing adoption of prefabricated building materials.

2.2 Xinshuo’s Sandwich Panel Production Line: A Game-Changer

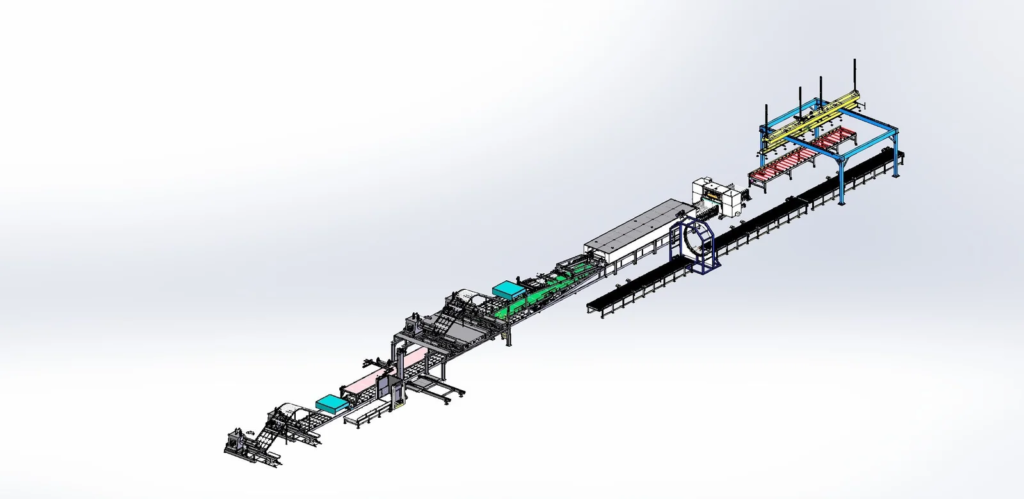

Xinshuo’s fully automatic sandwich panel production line is engineered to produce a wide range of panels, including rock wool, EPS, glass magnesium, and magnesium oxide sulfide varieties. This highly intelligent system streamlines the manufacturing process from raw material handling to finished product stacking, delivering unmatched efficiency and quality.

Unlike traditional semi-automated or manual production methods, Xinshuo’s line eliminates bottlenecks and reduces human error through end-to-end automation. This not only accelerates production but also ensures consistency, meeting the stringent standards required in modern construction and industrial applications.

2.2.1 Types of Sandwich Panels Produced

Xinshuo’s production line is versatile, capable of manufacturing multiple panel types to suit diverse needs:

- Rock Wool Sandwich Panels: Composed of mineral wool, these panels offer exceptional fire resistance (up to 1,000°C) and sound insulation (up to 30 dB reduction). They’re ideal for industrial facilities, warehouses, and buildings in fire-prone areas.

- Polystyrene (EPS) Sandwich Panels: Lightweight and affordable, EPS panels provide excellent thermal insulation (R-value of 3.8-4.5 per inch), making them perfect for cold storage, refrigerated warehouses, and energy-efficient structures.

- Glass Magnesium Sandwich Panels: Known for their moisture resistance and durability, these panels are suited for humid or corrosive environments, such as coastal buildings or chemical plants.

- Magnesium Oxide Sulfide Sandwich Panels: With enhanced chemical stability and strength, these panels are used in specialized applications requiring resilience against environmental stressors.

The ability to produce multiple panel types on a single line gives manufacturers flexibility to adapt to market trends and customer specifications without investing in separate equipment.

2.2.2 Production Process Breakdown

The Xinshuo sandwich panel production line operates as a continuous, automated system. Here’s a step-by-step overview of the process:

- Raw Material Preparation: Steel coils (0.4-0.8 mm thick) are loaded onto hydraulic uncoilers, which feed the material into the line. Automatic leveling and tension control ensure a smooth, flat surface.

- Roll Forming: The steel sheets pass through roll forming machines equipped with adjustable rollers, shaping them into profiles such as flat, corrugated, or ribbed surfaces. Quick-change mechanisms allow for rapid profile adjustments.

- Core Material Application: The core material is integrated based on the panel type. For rock wool or glass magnesium, pre-cut slabs are inserted via automated feeders. For EPS or PU, high-pressure foaming machines inject the material into the panel cavity with precision.

- Lamination: The assembled layers enter a double-belt laminating machine, where controlled heat (up to 60°C) and pressure (0.5-1 MPa) bond the core to the outer sheets, ensuring a strong, uniform structure.

- Cutting: Servo-driven cutting machines trim the continuous panel into specified lengths (typically 2-12 meters), with tolerances of ±1 mm. Edge trimming ensures clean, precise finishes.

- Stacking and Packaging: Robotic arms stack the finished panels into bundles (e.g., 10-20 panels per stack), which are then wrapped and prepared for shipment.

This streamlined process achieves production speeds of 8-10 meters per minute, translating to thousands of square meters per shift, depending on panel dimensions.

2.2.3 Technical Specifications

Xinshuo’s sandwich panel production line is packed with advanced features:

- Panel Width: Adjustable from 600-1,200 mm.

- Panel Thickness: 50-200 mm, customizable.

- Line Speed: Up to 10 m/min (adjustable via variable-frequency drives).

- Power Consumption: Approximately 150-200 kW, optimized for energy efficiency.

- Control System: PLC-based with touchscreen interface for real-time monitoring and adjustments.

- Material Compatibility: Galvanized steel, stainless steel, aluminum; core options include rock wool (50-150 kg/m³), EPS (12-20 kg/m³), and more.

These specifications ensure the line meets diverse production requirements while maintaining high output and precision.

2.3 Advantages of Xinshuo’s Sandwich Panel Production Line

Xinshuo’s system offers numerous benefits that set it apart from competitors:

- Full Automation: Eliminates manual labor in key stages, reducing costs by up to 50% and minimizing errors.

- High Output: Capable of producing 5,000-10,000 m² per day, ideal for large-scale projects.

- Precision: Servo motors and laser-guided systems ensure tolerances of ±0.5 mm, meeting international standards like EN 14509.

- Energy Efficiency: Variable-frequency drives (VFDs) and optimized heating reduce power usage by 20-30% compared to traditional lines.

- Durability: Constructed with high-grade steel and components, designed for 24/7 operation with minimal maintenance.

- Flexibility: Quick-change rollers and modular design allow for rapid reconfiguration between panel types.

These advantages translate into a strong return on investment (ROI), with many clients reporting payback periods of 2-3 years due to increased efficiency and reduced operational costs.

2.4 Applications of Sandwich Panels

Sandwich panels produced by Xinshuo’s line serve a wide array of industries:

- Industrial Construction: Warehouses, factories, and logistics centers benefit from rapid installation and insulation.

- Commercial Buildings: Retail spaces and offices use panels for aesthetic and functional walls and roofs.

- Cold Storage: EPS and PU panels maintain stable temperatures in refrigerated facilities.

- Residential Projects: Prefabricated homes leverage panels for cost-effective, energy-efficient construction.

- Transportation: Panels are used in refrigerated trucks and modular shelters.

The versatility of sandwich panels makes them indispensable in modern building design, and Xinshuo’s production line ensures manufacturers can meet this demand with high-quality output.

2.5 Case Study: Boosting Efficiency in a Construction Firm

A mid-sized construction materials manufacturer in Southeast Asia adopted Xinshuo’s sandwich panel production line in 2021. Previously relying on a semi-automated system, the company struggled with inconsistent quality and labor-intensive processes. After installing Xinshuo’s fully automated line, they reported:

- Production Increase: Output rose from 2,000 m² to 8,000 m² per day.

- Labor Reduction: Workforce decreased from 15 to 5 operators per shift.

- Energy Savings: Power consumption dropped by 25% due to VFDs.

- Client Satisfaction: Improved panel consistency led to a 30% increase in repeat orders.

This case illustrates how Xinshuo’s technology can transform operations, delivering tangible benefits in efficiency, cost, and market competitiveness.

3. Clean Room Sandwich Panel Production Line: Precision for Sensitive Environments

3.1 The Importance of Clean Rooms

Clean rooms are specialized environments designed to maintain extremely low levels of airborne contaminants, such as dust, microbes, and chemical vapors. They are critical in industries where contamination can compromise product integrity, safety, or research outcomes. Clean rooms are classified under standards like ISO 14644-1, ranging from ISO 1 (fewest particles) to ISO 9, based on particle counts per cubic meter.

Key factors in clean room design include air filtration (via HEPA or ULPA filters), temperature control (±0.5°C), humidity regulation (30-50%), and pressure differentials (positive or negative). The construction materials—particularly walls, ceilings, and floors—must be seamless, non-shedding, and resistant to contamination, making clean room sandwich panels a vital component.

The global clean room technology market is expanding rapidly, valued at $5 billion in 2022 and projected to grow at a CAGR of 6-8% through 2030, fueled by demand in pharmaceuticals, electronics, and biotechnology.

3.2 Xinshuo’s Clean Room Panel Production Line

Xinshuo’s clean room sandwich panel production line—also known as the purification box panel line—is engineered to produce panels that meet the rigorous demands of controlled environments. These panels feature dust-proof, anti-static, and antibacterial properties, making them ideal for high-stakes applications.

3.2.1 Features of Clean Room Panels

- Dust-Proof Design: Smooth, non-porous surfaces prevent particle accumulation.

- Anti-Static Coating: Reduces static electricity (surface resistivity of 10⁶-10⁹ ohms), critical for electronics manufacturing.

- Antibacterial Properties: Specialized coatings inhibit microbial growth, achieving a 99.9% reduction in bacteria like E. coli.

- Air-Tight Sealing: Interlocking joints and silicone gaskets maintain pressure differentials (e.g., 10-20 Pa).

- Thermal Stability: Insulation maintains temperatures within ±1°C, reducing energy costs.

- Chemical Resistance: Withstands disinfectants like hydrogen peroxide without degradation.

These attributes ensure compliance with standards like GMP (Good Manufacturing Practice) and ISO 5-8 classifications, commonly required in clean room construction.

3.2.2 Production Process

The production process mirrors the sandwich panel line but includes additional steps for clean room specifications:

- Material Prep: High-quality steel (e.g., 304 stainless) is uncoiled and leveled.

- Forming: Roll formers shape the steel with precision (±0.2 mm tolerance).

- Core Insertion: Antibacterial or anti-static cores (e.g., rock wool or PU) are applied.

- Lamination: Double-belt press ensures seamless bonding.

- Coating: Anti-static or antibacterial layers are applied via spray or roll coating.

- Quality Check: Inline sensors test surface resistivity, smoothness, and dimensional accuracy.

- Packaging: Panels are sealed in clean conditions to prevent contamination.

The line operates in an enclosed, filtered environment to maintain panel purity during production.

3.3 Applications of Clean Room Panels

- Pharmaceuticals: Sterile drug production and packaging (e.g., ISO 5 clean rooms).

- Electronics: Semiconductor and microchip manufacturing (e.g., ISO 3-4).

- Biotechnology: Vaccine development and gene therapy labs.

- Aerospace: Assembly of precision components like satellite parts.

- Food Industry: Hygienic packaging and processing areas.

- Healthcare: Operating theaters and diagnostic labs.

These applications highlight the critical role of clean room panels in maintaining product safety and quality.

3.4 Advantages and Innovations

Xinshuo’s clean room panel line offers:

- High Precision: Tolerances of ±0.2 mm ensure seamless installation.

- Customization: Options for embedded conduits or reinforced edges.

- Innovations: Smart panels with sensors for real-time environmental monitoring.

These features position Xinshuo as a leader in clean room manufacturing technology.

4. C&Z Steel Purlins Automatic Production Line: Structural Strength Meets Automation

4.1 What Are C&Z Steel Purlins?

C&Z steel purlins are cold-formed structural members used in steel-framed buildings to support roofs and walls. Their shapes—‘C’ (with perpendicular flanges) and ‘Z’ (with angled flanges)—offer distinct advantages in load distribution and installation.

- C Purlins: Simple design for walls or short spans.

- Z Purlins: Overlapping capability for longer spans in roofing.

Made from galvanized steel (e.g., G550 grade), they’re lightweight yet strong, widely used in industrial, agricultural, and commercial construction.。

4.2 Xinshuo’s C&Z Purlin Production Line

Xinshuo’s fully automatic C&Z purlin production line handles the entire process—from unwinding to stacking—with precision and speed:

- Unwinding: Hydraulic uncoilers feed steel coils (1.5-3 mm thick).

- Forming: Adjustable roll formers shape C or Z profiles (80-300 mm depth).

- Punching: Servo-driven stations punch holes (e.g., 14-18 mm diameter).

- Cutting: Hydraulic shears cut lengths (2-12 m) with ±1 mm accuracy.

- Stacking: Automated stackers organize purlins for shipping.

Production speeds reach 20-30 m/min, with daily outputs of 10,000-15,000 meters.

4.3 Benefits and Applications

- Efficiency: High-speed production reduces lead times.

- Versatility: Adjustable settings for various purlin sizes.

- Applications: Warehouses, barns, factories, and commercial sheds.

Integration with LMS enhances monitoring and optimization, ensuring peak performance.

5. Integrated Production Lines and Retrofitting: Modernizing Legacy Systems

Xinshuo’s retrofitting services upgrade old equipment with automation, controls, and energy-efficient components, extending lifespan and performance. Benefits include cost savings, reduced downtime, and improved output, making it a practical alternative to full replacements.

6. Laser Cutting Services: Precision Engineering

Xinshuo’s laser cutting services offer high-precision cutting (±0.1 mm) for steel and other materials, supporting custom components for panels and purlins. This enhances flexibility and reduces waste.

7. Line Management System (LMS): Intelligent Factory Management

LMS, Xinshuo’s proprietary system, optimizes production with real-time monitoring, remote control, and data analytics. It reduces costs by 15-20% and boosts efficiency, aligning factories with Industry 4.0 standards.

8. About Xinshuo

Xinshuo Intelligent Production Line offers a holistic approach to modern manufacturing, delivering automation, precision, and intelligence across sandwich panels, clean room panels, and C&Z purlins. Contact Xinshuo to explore how their solutions can transform your factory.